Carrying out a Feasibility Study

Practical Action

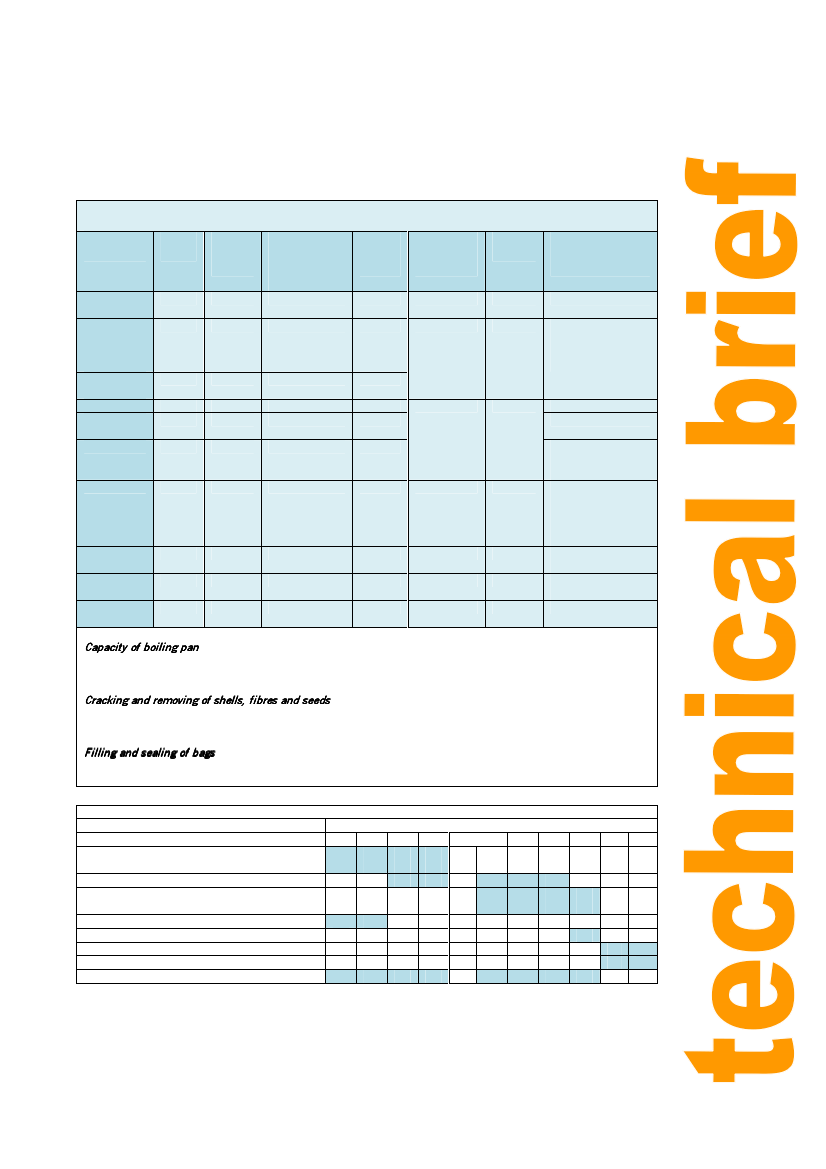

Example: Modified process chart for production of tamarind pickle.

This chart shows the scale of operation and daily requirements for production, including

quantities of raw materials needed, capacity of equipment and number of workers to

complete the required production level in one day.

For the production of approximately 35.6kg pickle, about 45kg tamarind pods are needed.

Modified process chart showing scale of operation and daily requirements for processing of tamarind

pickle:

Processing % Weight Weight of Batch Processing No of Minimum

stage

losses of fruit

other

size

time

workers equipment size

(kg) ingredients (kg) (minutes)

(kg/hr)

(kg)

Tamarind

45

Scale

pods

Crack and

11

40

240 2 Table or canvas

remove

cover for 2 workers,

shells and

plastic bowls,

fibres

containers

Remove

34 26.4

seeds

Add sugar

5 26.4

26.4

50.2

240

1 Scale

Add spice

5 26.4

13.0

60.0

Mortar and pestle

mix

Boil 34

39.6

Cooker or stove, 12-

15l boiling pan,

wooden spoon

Fill and seal 10

35.6

180

2 Table, measuring

jug, jars and lids (or

plastic bags),

capping or sealing

machine

Cool and

35.6

120

1 Labels and label

label

gummers

Store

35.6

Cool, dark room,

shelves

Weight of

35.6

product

Notes on calculations:

Capacity of boiling pan

If each batch takes approximately 30 minutes to boil, 1.5 batches can be prepared per hour. In order to meet the

production target of 60kg raw material, yielding 35.6kg of product every day, 4 hours are needed to prepare 6

batches of 10kg each. The boiling pan should therefore have a capacity of 12-15 litres.

Cracking and removing of shells, fibres and seeds

It requires 8 man-hours to shell and de-seed 45 kg fruit. Two workers are needed to complete this task in 4 hours.

Since tamarind pulp can easily be stoned without deterioration, the cracking and removing of shells, fibres and seeds

could be carried out in advance.

Filling and sealing of bags

Each worker can fill and seal 40 jars or bags of 150g weight per hour. 35.6kg produces 237 bags of jars. Two

workers are needed to complete this activity in 3 hours.

Activity chart used to plan allocations of staff to produce tamarind pickle

Hours during working day

Activity

8 9 10 11 12 13 14 15 16 17

Cracking/removing seeds

X, X, X, X, L

YYYY

Mixing/boiling

Z ZUZ Z Z

Filling/sealing

N X, X, X, X,

YYYY

Labelling

ZZ

C

Cleaning

HZ

Store management

ZZ

Distribution

MM

Management

MMMM

MMMM

X,Y,Z = permanent workers; M = manager and owner of the enterprise

Ref: Technical manual for small scale fruit processors, ICUC.

6